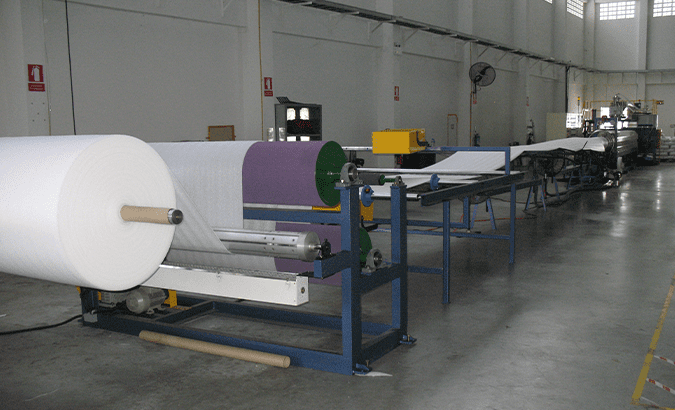

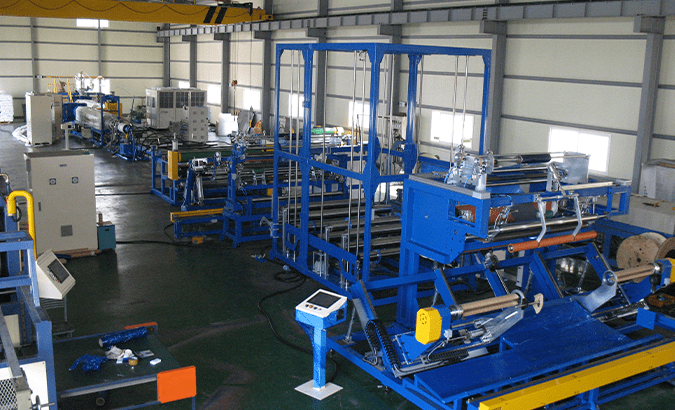

PE Foam Sheet Extrusion Line

PE Foam Sheet Extrusion Line is equipped with a single extruder, an economical extruding system for the production of extruded expanded cellular Polyethylene

foam sheet consisting of innumerable closed cells, in continuous roll from low density Polyethylene, using Butane, eco-friendly blowing agent and other additives.

Applications

Shock Absorbing, Resilience, Non-abrasive surface Water Proofing, Extremely low moisture absorption, Thermal Insulation.

Flexible and Easy Handling, Easy Laminating, Easy Punching, Strong Chemical Resistance, Non-Hazardous.

Thanks to these superb properties of PE foam, they serve diverse industries.

- Cushioning and packaging materials for electronic equipments, potteries, glassware etc.

- Construction-roof insulation, expansion joints, anti- vibration in roofs, walls, tunnels, bridges, highways and etc.

- Insulation of window, Air conditioner ducting, industrial chillers, cold storage, refrigerated vans, industrial refrigerators, water-pipe and etc.

- Education materials, decorating objects.

- Insects and rodents will not eat it. Thin, flexible , UV resistant.

-

Sport-wrestling, judo, gym and jogging exercise mats, body protecting materials like helmet, leg and thigh guards,

arm/elbow/shoulder pad, life saving jackets, gloves and so on.

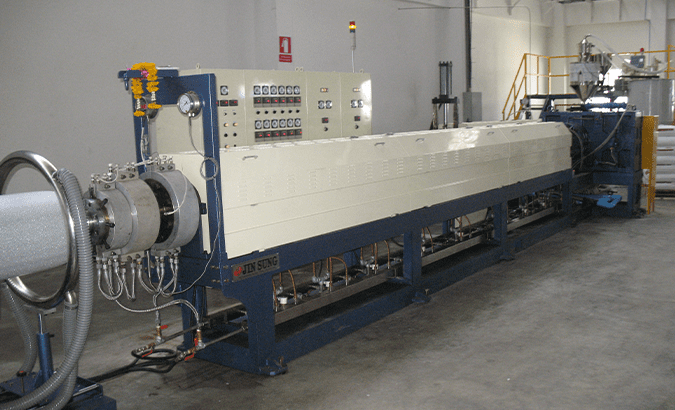

High Quality & Superior Output

-

JIN SUNG Machinery's Single Extruder, an integral component of the PE Foam Sheet Extrusion Line, which is an economical solution for Polyethylene foam

extrusion compared to a tandem extruder, melts Polyethylene, intensively mixes it with other additives cools and transports them to the foam die,

enabling an optimal foaming and maximum output. - JIN SUNG Machinery's unique Screw provides an intensive mixing, enabling the production of quality foam sheet with virtually any cell size and density.

-

JIN SUNG Machinery's Dies, the other integral component of the PE Foam Sheet Extrusion Line, are specially manufactured for its high tolerances and provides

an efficient process and flexibility to create the highest quality foam to meet today's diverse needs.

Specifications

If you cannot see the text, click on the area and scroll left and right.

| Model | JS-PE 105 |

JS-PE 120 |

JS-PE 130 |

JS-PE 150 |

JS-PE 180 |

JS-PE 200 |

JS-PE 130 170 |

JS-PE 150 200 |

JS-PE 200 250 |

|---|---|---|---|---|---|---|---|---|---|

| Width (mm) | 800-1600 | 800-1600 | 800-1600 | 800-1600 | 800-2000 | 1000-2200 | 1000-2200 | 1000-2200 | 1000-2200 |

| Thickness (mm) | 0.5-6 | 0.5-8 | 0.5-10 | 0.5-15 | 1-20 | 2-20 | 0.5-10 | 1-15 | 2-20 |

| Screw Dia. (mm) | 105 | 120 | 130 | 150 | 180 | 200 | 130 & 170 | 150 & 200 | 200 & 250 |

| Capacity (mm) | 80 ~ 170 | 80 ~ 230 | 80 ~ 290 | 100 ~ 370 | 150 ~ 470 | 200 ~ 600 | 130 ~ 330 | 160 ~ 470 | 300 ~ 700 |